SERVICES

Printing

Multiple Line

Multiple Line

Electronic Line Shaft LS -250 metres per min.

Turret Type Unwinder /rewinder with flying facilities automatic reel change over without stopping machine , minimum wastage.

Shaft less trolley system , fast changeover.

Automatic register Control system and Automatic defect detection system.

Online Viscosity Pump for solvent , Ink Circulation pump.

Turret Type Unwinder /rewinder with flying facilities automatic reel change over without stopping machine , minimum wastage.

Shaft less trolley system , fast changeover.

Automatic register Control system and Automatic defect detection system.

Online Viscosity Pump for solvent , Ink Circulation pump.

Inspection/Doctoring

Machine

Machine

Maximum speed - 400 m/min

Maximum web width - 1200mm

Shaftless unwinder & rewinder

Movable operating panel can be operated from front as well as back side of the machine

Machine is mainly used for inspection of multicolor printed film for registration, & all other printing defects

Rewinders upper rewinder for separation of defective printed material

Trim blower arrangement for single coil slitting facility

Maximum web width - 1200mm

Shaftless unwinder & rewinder

Movable operating panel can be operated from front as well as back side of the machine

Machine is mainly used for inspection of multicolor printed film for registration, & all other printing defects

Rewinders upper rewinder for separation of defective printed material

Trim blower arrangement for single coil slitting facility

Extrusion Lamination

Machine

Machine

Maximum speed - 200m/min

Maximum web - width -1200mm (+-)

Substrates to be laminate:

4 PLY - Paper + Poly + Foil + Poly Coated

4 PLY- Paper + Pet + Poly + Foil

3 PLY- Pet + Poly + Met Pet /Met BOPP

PLY- Pet + Poly Coated

S2 PLY- Paper + Poly Coated

2 PLY- Printed BOPP + Met BOPP

2 PLY- Printed CPP + Poly Coated

Maximum web - width -1200mm (+-)

Substrates to be laminate:

4 PLY - Paper + Poly + Foil + Poly Coated

4 PLY- Paper + Pet + Poly + Foil

3 PLY- Pet + Poly + Met Pet /Met BOPP

PLY- Pet + Poly Coated

S2 PLY- Paper + Poly Coated

2 PLY- Printed BOPP + Met BOPP

2 PLY- Printed CPP + Poly Coated

Solvent Base

Lamination

Lamination

Make- S.P. Ultra Flex./S.P. Ultra Flex.

Maximum Width 1200mm / Speed 350/200mpm

Superior Solvent-based Lamination for enhanced shelf life

Excellent Bond Strength

Effective Sealability of laminates

high barrier properties extend shelf life of product

Excellent Bond Strength

Resistance to Chemicals, Moisture etc.

Maximum Width 1200mm / Speed 350/200mpm

Superior Solvent-based Lamination for enhanced shelf life

Excellent Bond Strength

Effective Sealability of laminates

high barrier properties extend shelf life of product

Excellent Bond Strength

Resistance to Chemicals, Moisture etc.

Solvent Less

Lamination

Lamination

Maximum Speed – 350m/min

Maximum Web –width -1330mm

Shaftless Unwinder& rewinder

Maximum Web –width -1330mm

Shaftless Unwinder& rewinder

High Speed Slitter

Machine

Machine

Maximum Speed – 500m/min

Maximum Web –width -1330mm

Shaftless Unwinder& rewinder

Unwind Tension control

Differential Winding System

Maximum Web –width -1330mm

Shaftless Unwinder& rewinder

Unwind Tension control

Differential Winding System

Multilayer Blown

Film Lines -2

div class="fes2-text-cont"> Daily Output of 10 TonsFilm Lines -2

Multi-Layer Blown Polyethylene (PE) Lines

High Performance sealant layer

Minimum thickness 20 micron

Capable of handling speciality polymers

Pouching

Multiple Lines

Multiple Lines

Centre-seal, 3-sideseal, stand-up, gusseted pouches with zipper facility

Suitable Laminated Pouches and Bags for Packing in 1 gm to 25 Kgs

In house pouching Capacity of 2Cr.Pouches per months(All type Pouches)

Suitable Laminated Pouches and Bags for Packing in 1 gm to 25 Kgs

In house pouching Capacity of 2Cr.Pouches per months(All type Pouches)

PVC sleeve gluing

Machine

Machine

Maximum tubing width - 300mm

Maximum machine speed - 100 m/min

Machine is mainly used for tube making of PVC / pet printed / unprinted sleeves

Maximum machine speed - 100 m/min

Machine is mainly used for tube making of PVC / pet printed / unprinted sleeves

PVC sleeve cutting

Machine

Machine

Maximum tubing width - 300mm

Maximum machine speed - 350 pcs/min

Machine is mainly used for cutting of PVC / pet printed / unprinted sleeves

Maximum machine speed - 350 pcs/min

Machine is mainly used for cutting of PVC / pet printed / unprinted sleeves

Side seal

Machine

Machine

Maximum tubing width - 290mm

Maximum machine speed - 150 m/min

Machine is used for gusseted or non-gusseted tube making of single layer LD, HM, PP, bags

Online gusset facility is available on the machine

Maximum machine speed - 150 m/min

Machine is used for gusseted or non-gusseted tube making of single layer LD, HM, PP, bags

Online gusset facility is available on the machine

GREEN INITIATIVE

SOLAR POWER PLANT

INFRASTRUCTURE FOR QUALITY PRODUCT

QA, QC Testing Lab. and Quality Control Department (Like Testing and Documentation processes).

| # | DESCRIPTION | QUALITY PARAMETER | CAPACITY (Range) | UNIT'S |

|---|---|---|---|---|

| 1 | Universal Tester Machine | Strength of Bond, Tensile & Seal | 0 to 50 kg. | kg |

| 2 | Dart Impact Tester | Poly Dart | 0 to 3645gm. | gm |

| 3 | Static & Kinetic Friction Tester | C O F | 0.000 to 9.999kg | kg |

| 4 | Hot Air Oven | Green Bond of laminates | 0.0 to 250.0 deg c | deg c |

| 5 | Electronic Balance | GSM of laminates | 0 to 220gm | gm |

| 6 | Micro Meter | To Check micron of Plastic | 0 to 1000μ | μ |

| 7 | Optical Densitometer | To Check OPD of MET PET, MET BOPP | 0 to 4.00d | densitometer |

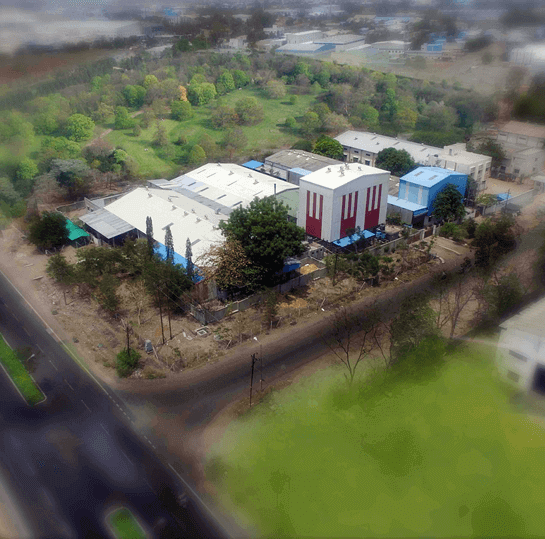

WE LOCATED AT

WALUJ, MIDC, AURANGABAD,

MAHARASHTRA, INDIA.